For additional details or improvements of snow cat models we developed a couple of 3D printed parts in scale 1:12. These can be ordered in our Thangs-Shapeways-Webshop.

The rather high prices for some parts are from Shapeways. Our margin is only a few Euros.

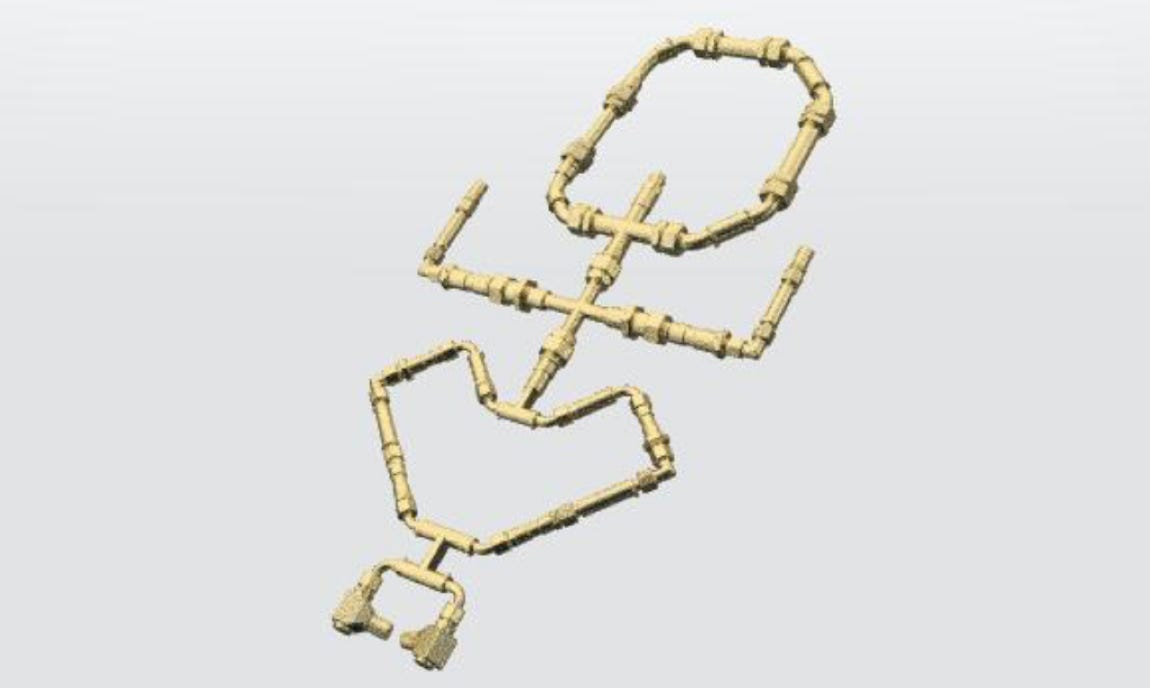

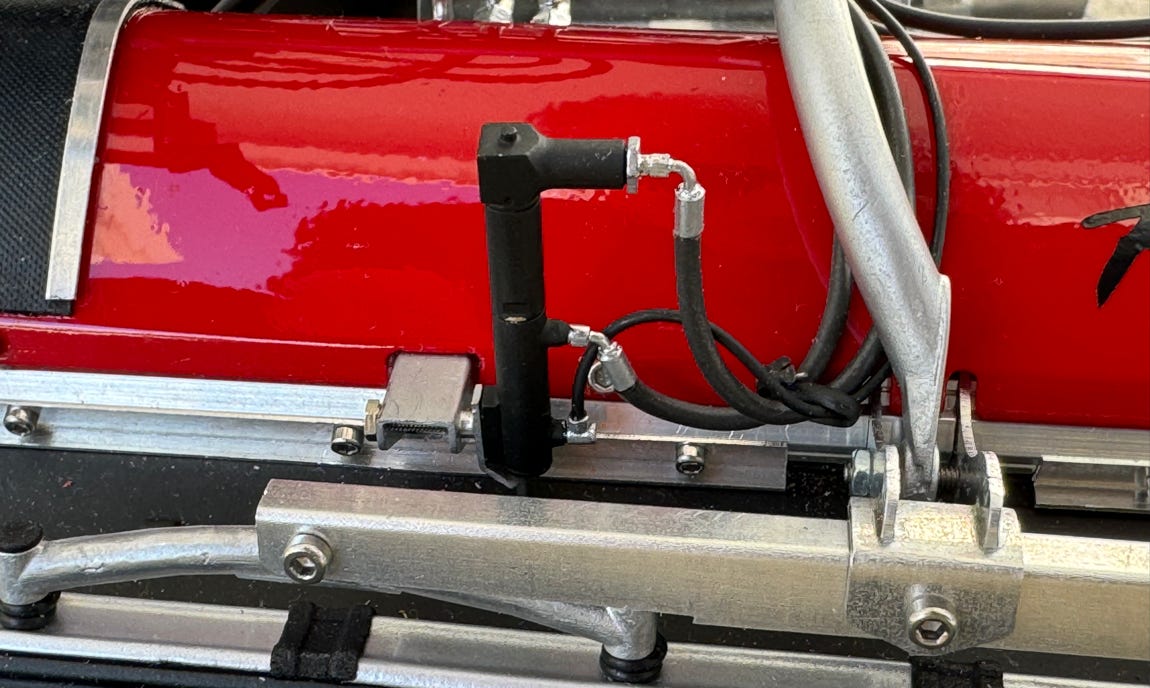

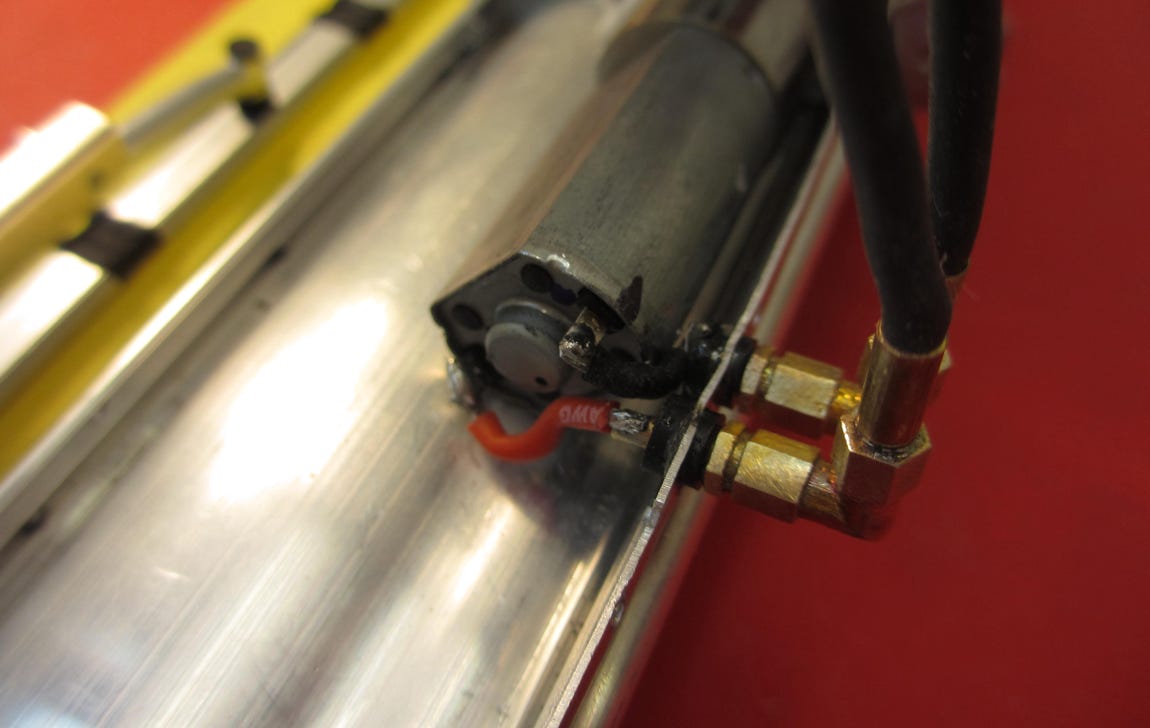

With this 3D-printed part, the hydraulic connectors (dummy) for the front Pistenking equipment carrier can be built true to the original. Brass tubes and silicone strands are also required.

With this 3D-printed part, the hydraulic connectors (dummy) for the Pistenking blade side cylinders can be built true to the original. Brass tubes and silicone strands are also required.

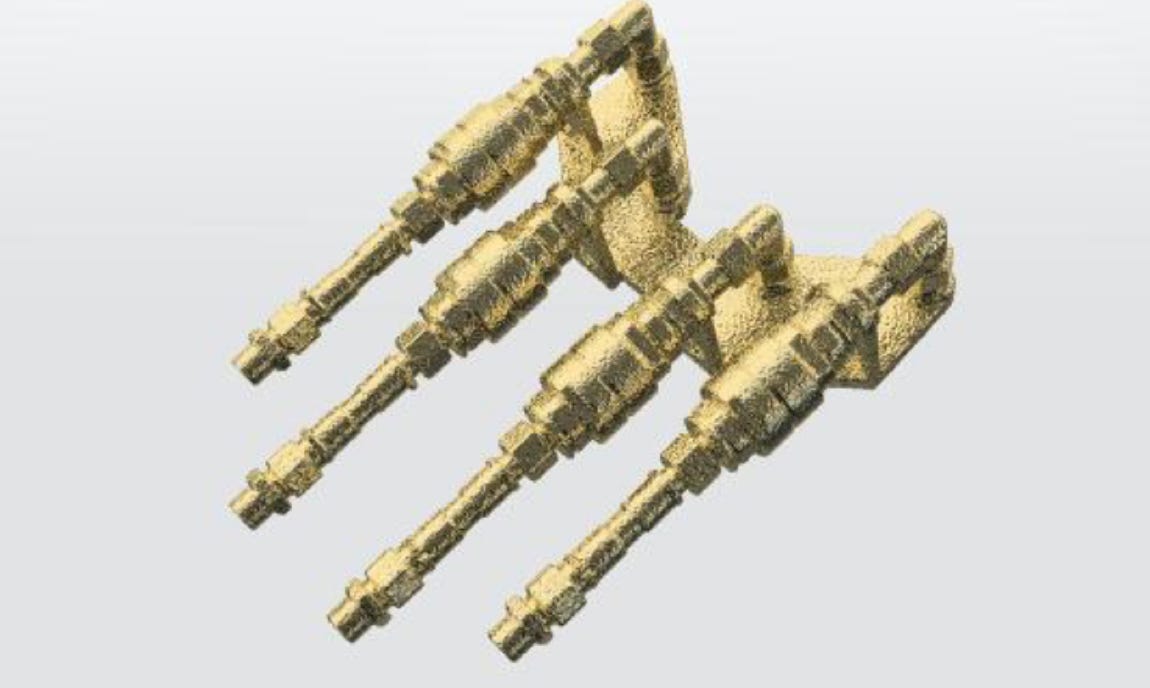

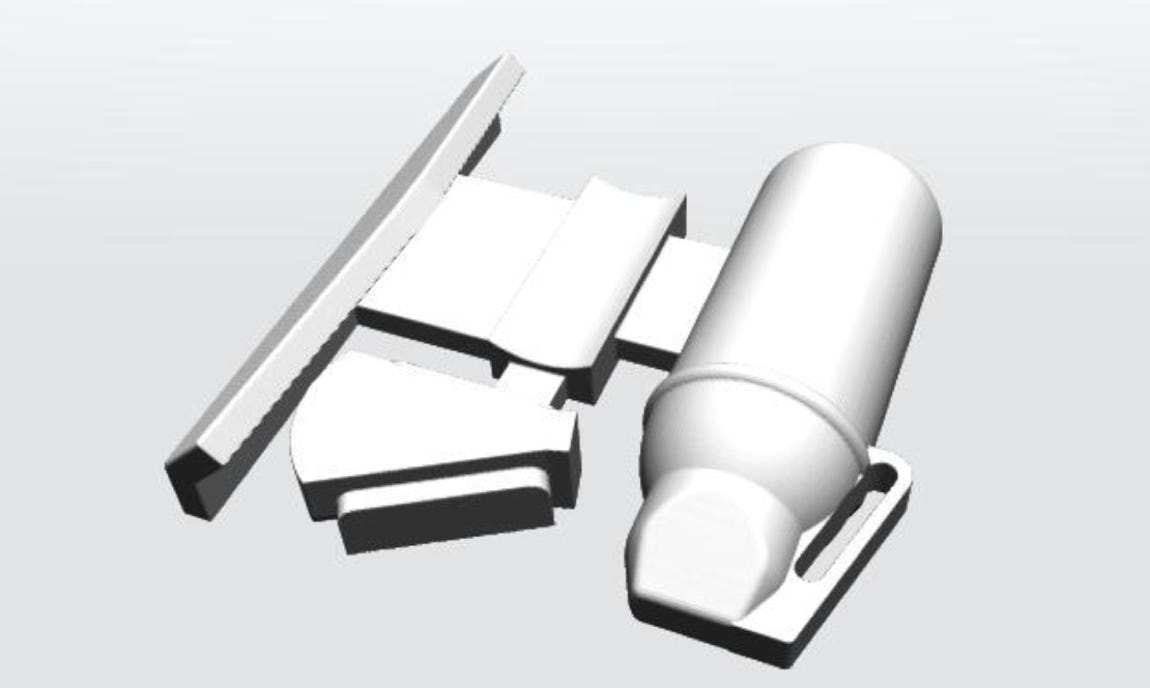

With this 3D-printed part, the two flap cylinders can be recreated true to the original. An additional 2 mm round steel pieces are necessary for the piston rods. We recommend brass for stability reasons.

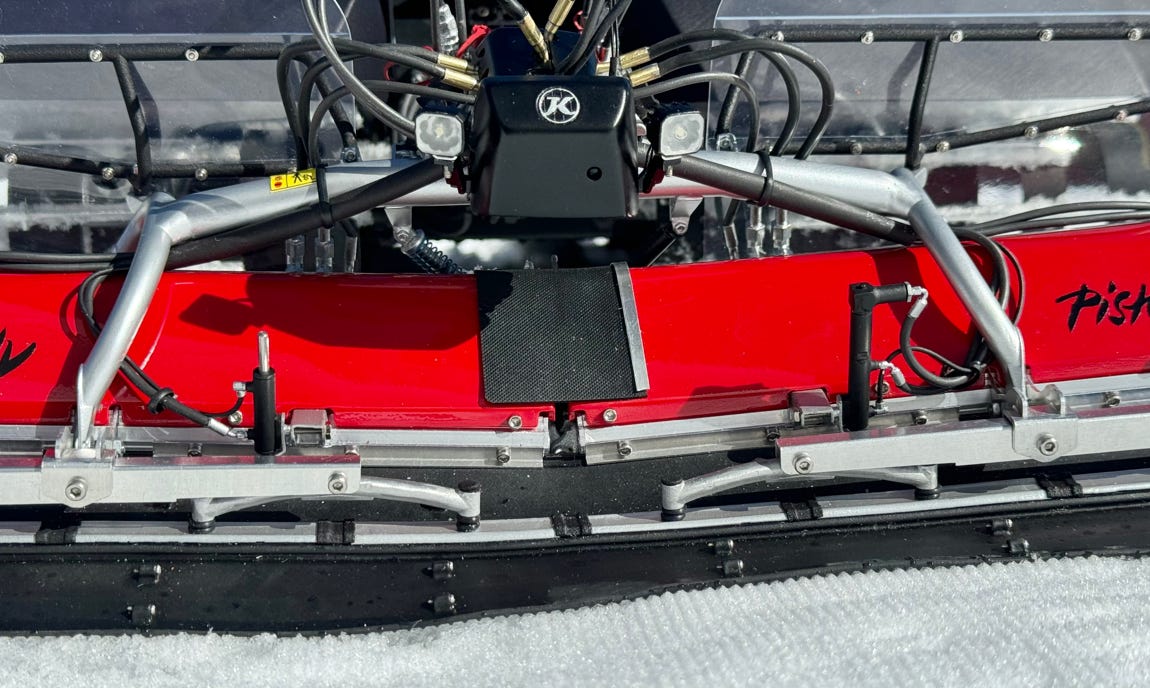

The mounting brackets for the flap cylinders are simply screwed onto the tiller box. There are also original hydraulic connections for the flap cylinders, side finisher cylinders and lifting cylinders suitable for the Pistenking AlpinFlex tiller.

With this 3D printed part a fire extinguisher + foot rest can be made. The decal will be mailed after ordering. It is available in scales 1:12 and 1:8. The part is currently not available because we ran out of decals in 1:12. If interested, please let us know.

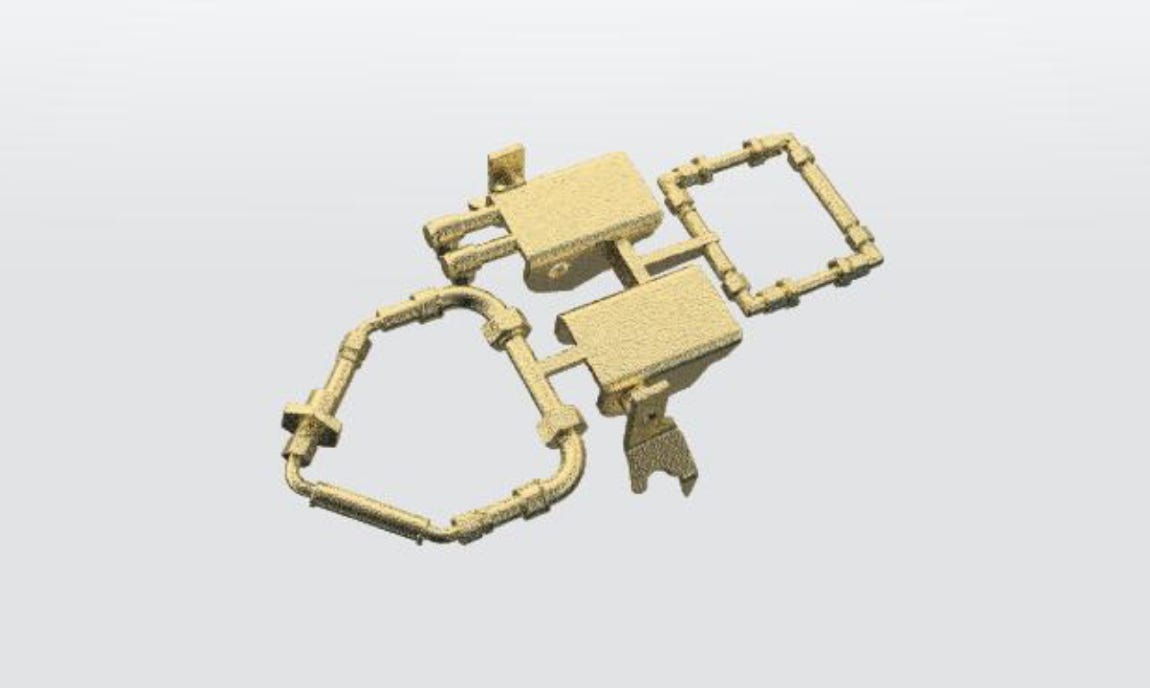

These reinforcement frames can be glued into the vacuum formed covers of the Pistenking 4.0 to winch. It is one part for both frames which needs to be cut. Slight adaptions are necessary.

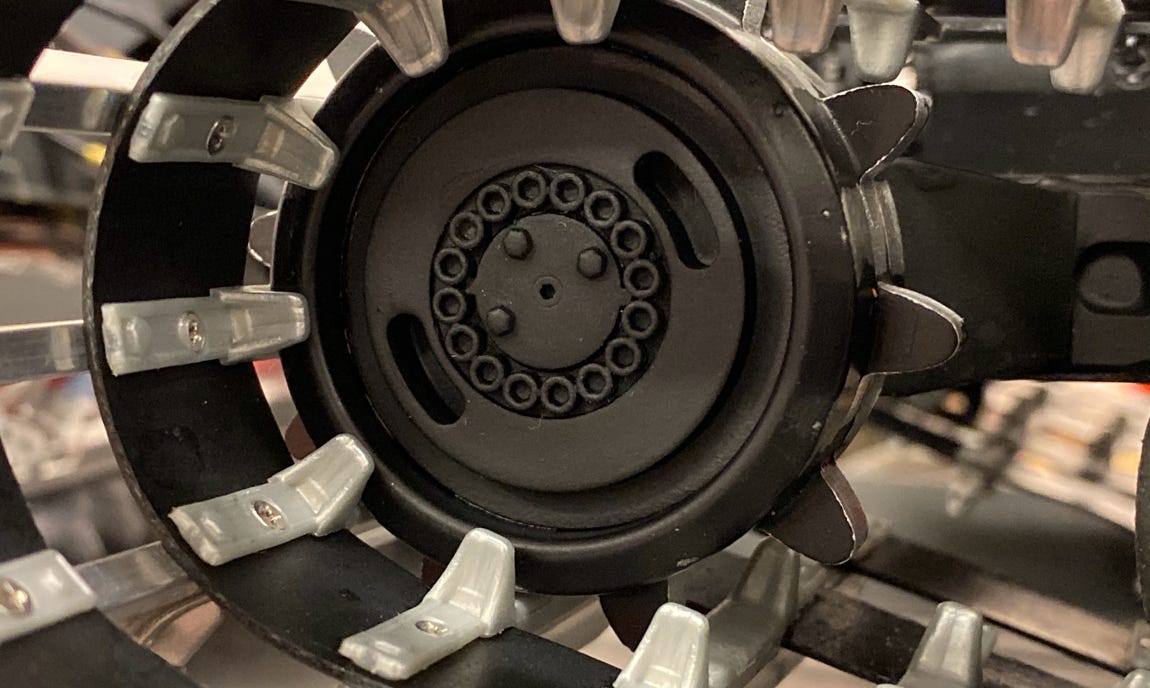

Insert fitting into the Pistenking sprocket for newer wheel hub types. Depending on the year either the original Pistenking hub or also this hub are used at the originals.

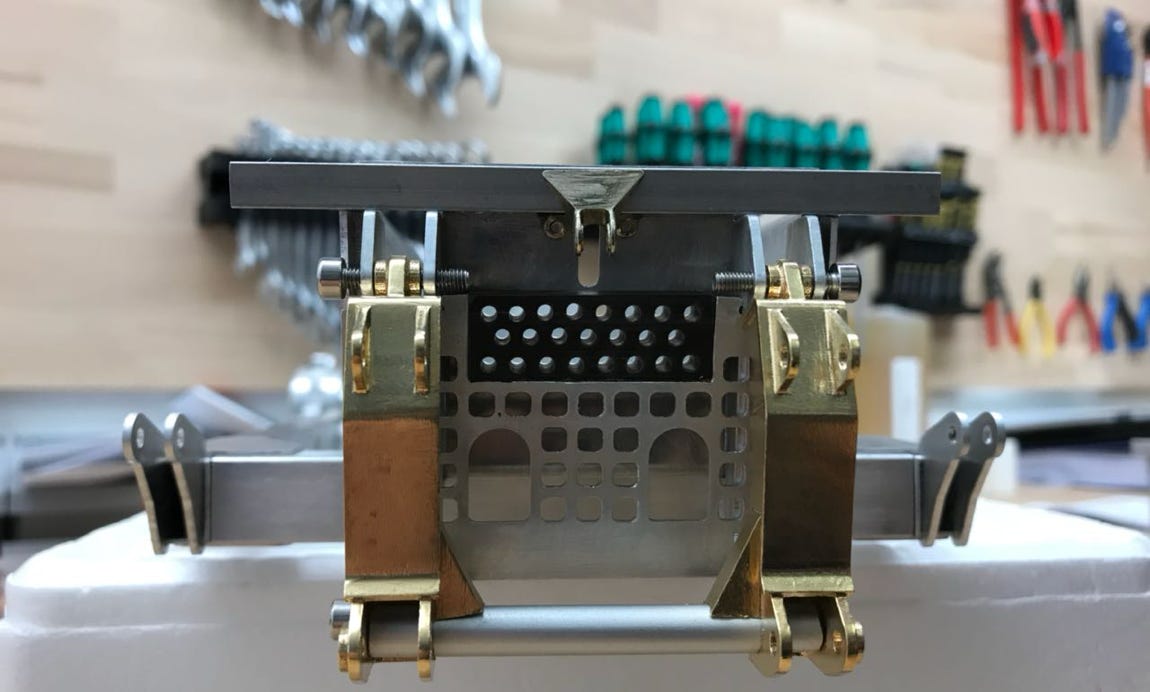

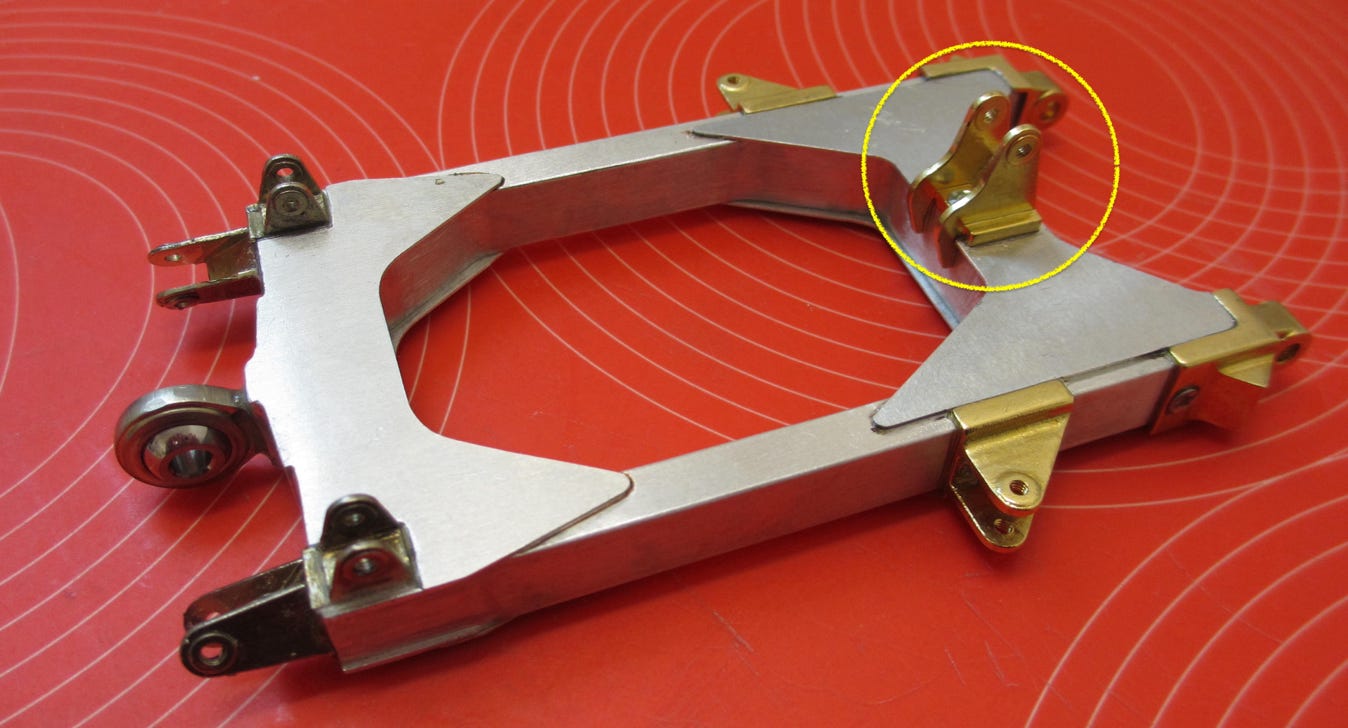

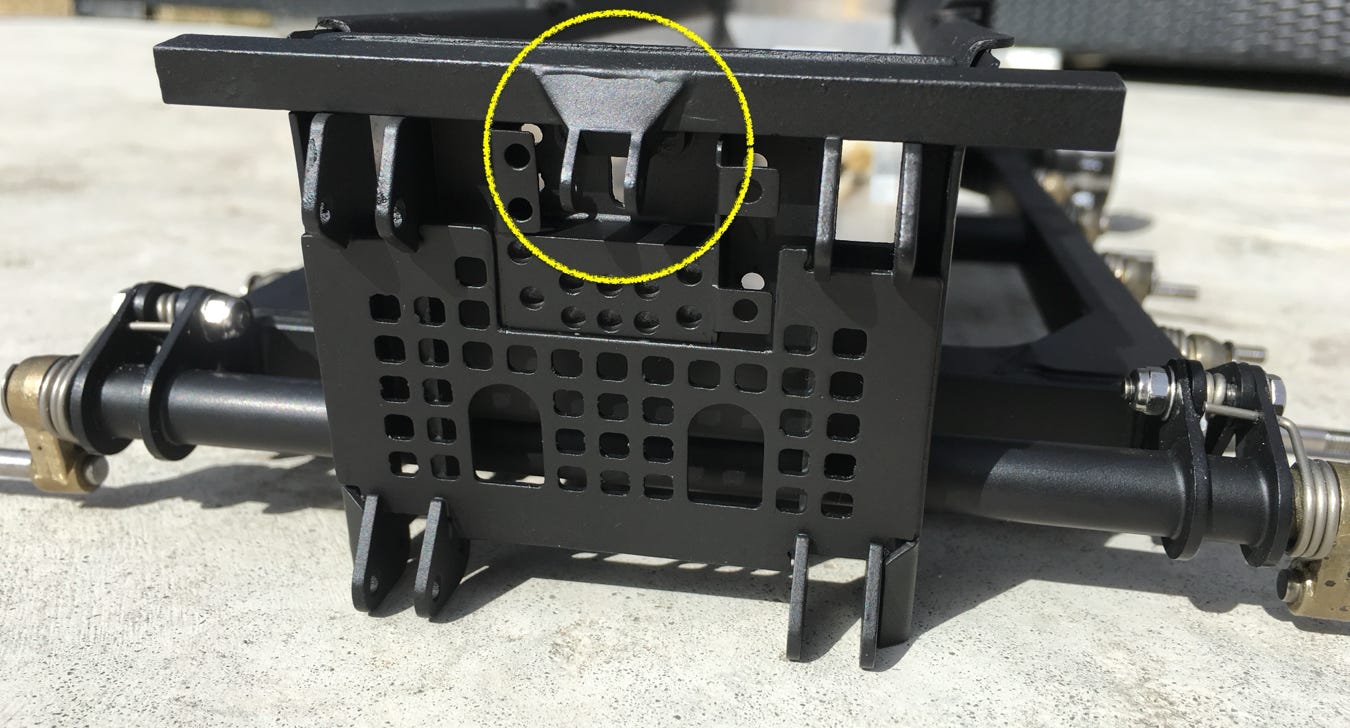

At the PistenBully 600 and 400 Park (not ParkPro!) the front attachment carrier is mounted on these parts. They fit for the Pistenking chassis. The left and right part are needed as well as a 6 mm brass tube to connect both parts at their lower end.

If you are interested, please get in touch. These large brass parts are relatively expensive at Shapeways and there may be cheaper printing services available.

Photo by Constantin Woywod

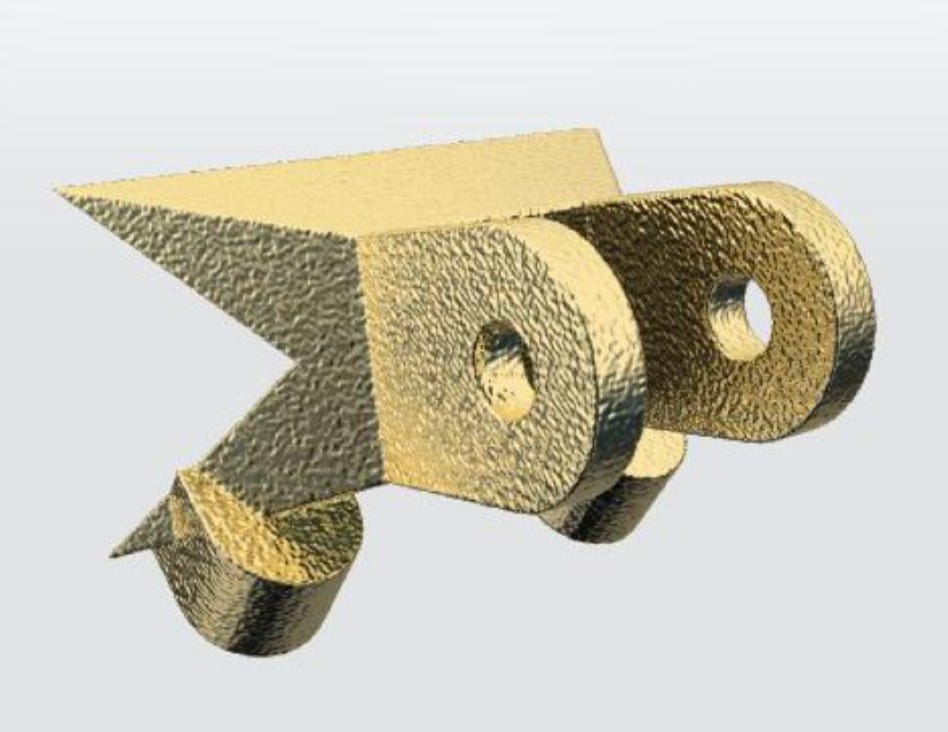

At all PistenBully 400 and 600 Park versions the blade cutting angle cylinder is attached directly to the pushing frame. That's what this part is used for.

This part replaces the mounting fork at the Pistenking chassis for ball heads with 5mm width. That might be needed for some hydraulic cylinders.

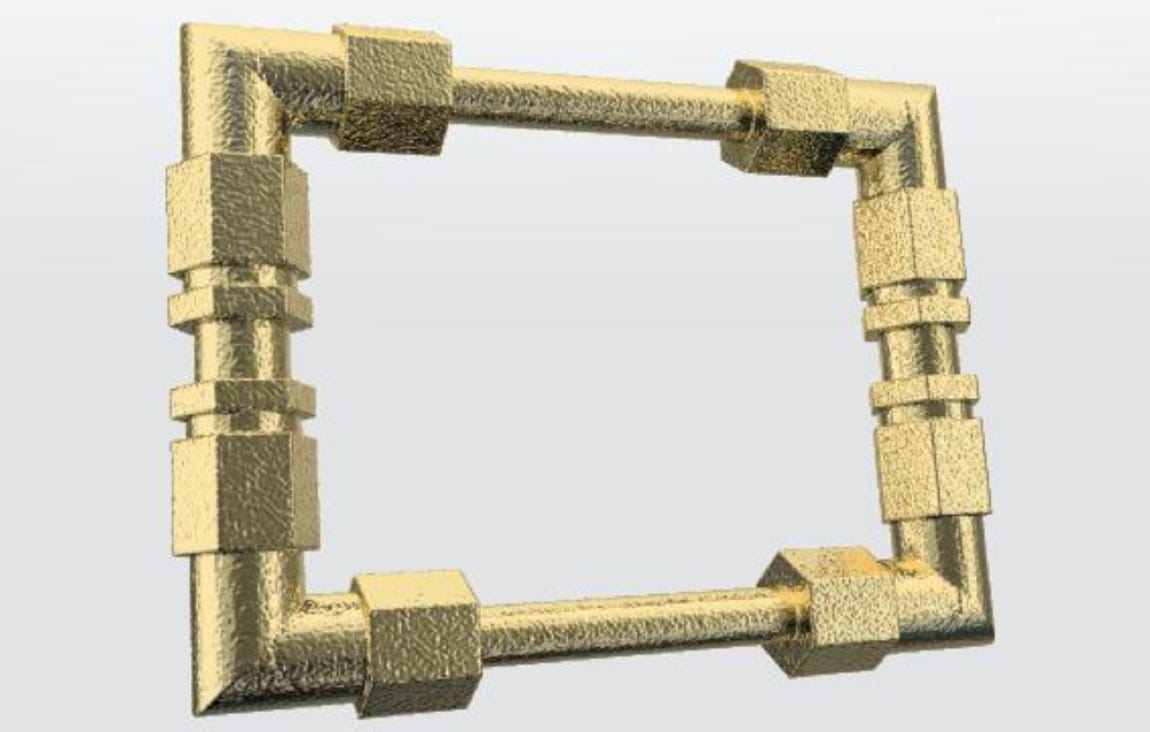

These parts allow a scale representation of the power cables to the tiller wheel motors. The 4 parts are combined to a ring to reduce printing costs and must be cut apart.